Pulleys and timing belts – strong together

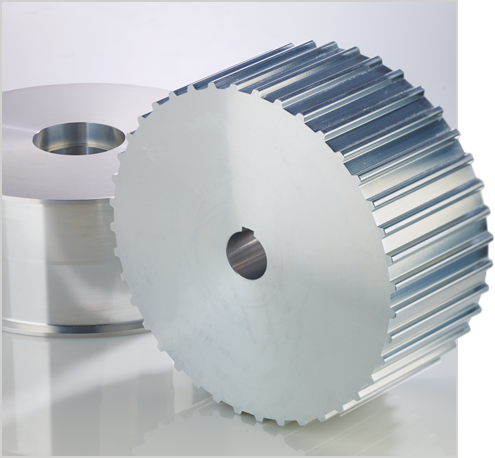

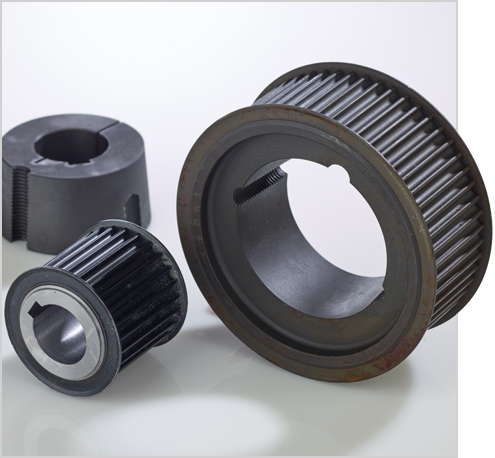

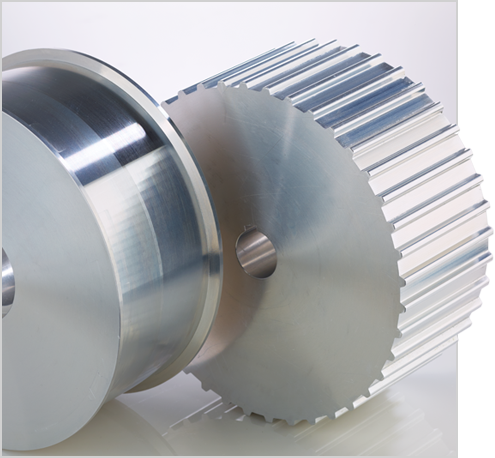

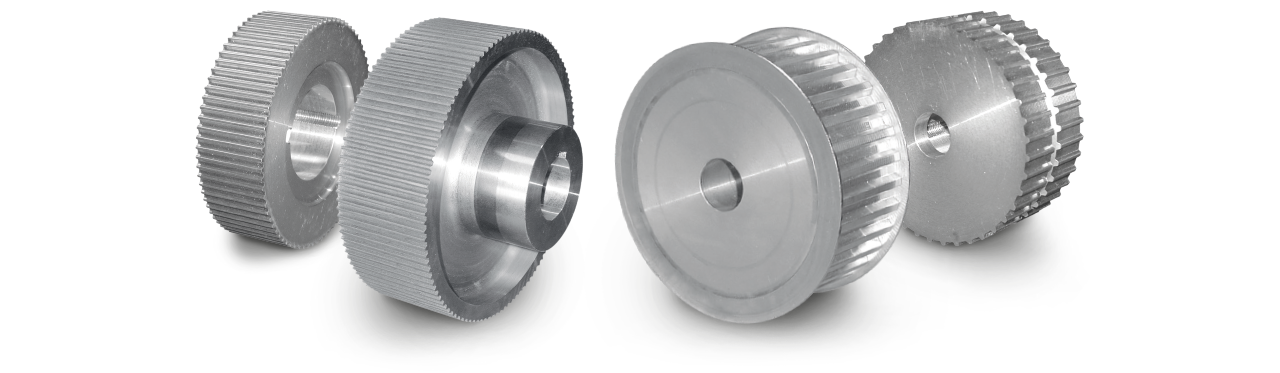

The quality of the toothed pulleys is of great importance for the function and service life of the timing belt. We therefore recommend that our customers use the appropriate toothed pulleys for our timing belts. The decisive factor for the high quality of our toothed pulleys is a constant quality control, in particular the precise execution of the tooth gaps and division equality. The adherence to the lowest tolerances according to the applicable ISO standards is our top priority.

We also supply special toothed pulleys in aluminum alloy (AlCuMgPB), steel or gray cast iron – either as a single piece or in small and medium series. All cutters for the most common tooth profiles

the T and AT series, HTD, STD, RTD and Eagle and other special toothed pulleys are available. If desired, we also use other materials, such as plastics and stainless steel, or an additional surface finish, for example a wear-resistant coating.