Our drive technology is your optimal transit times.

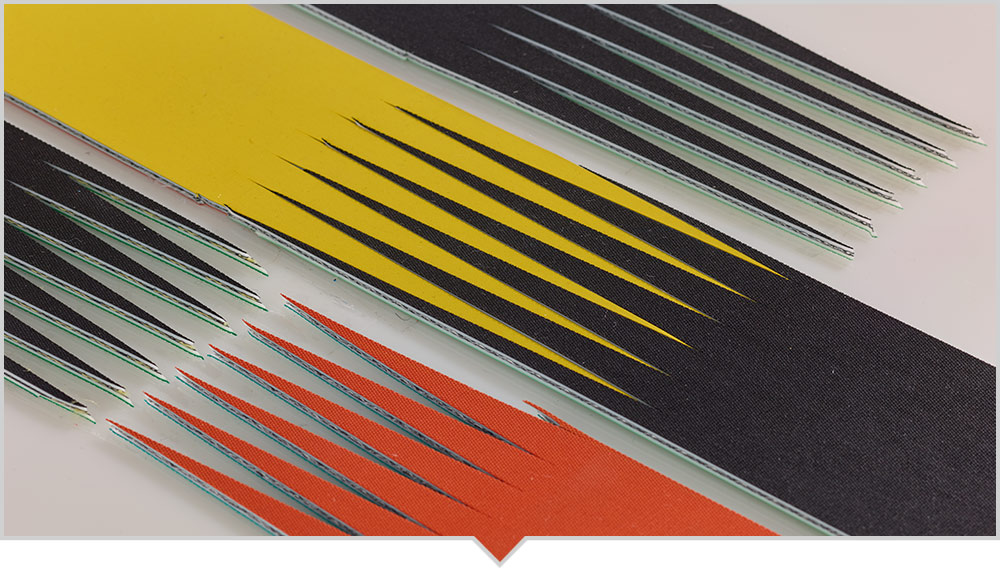

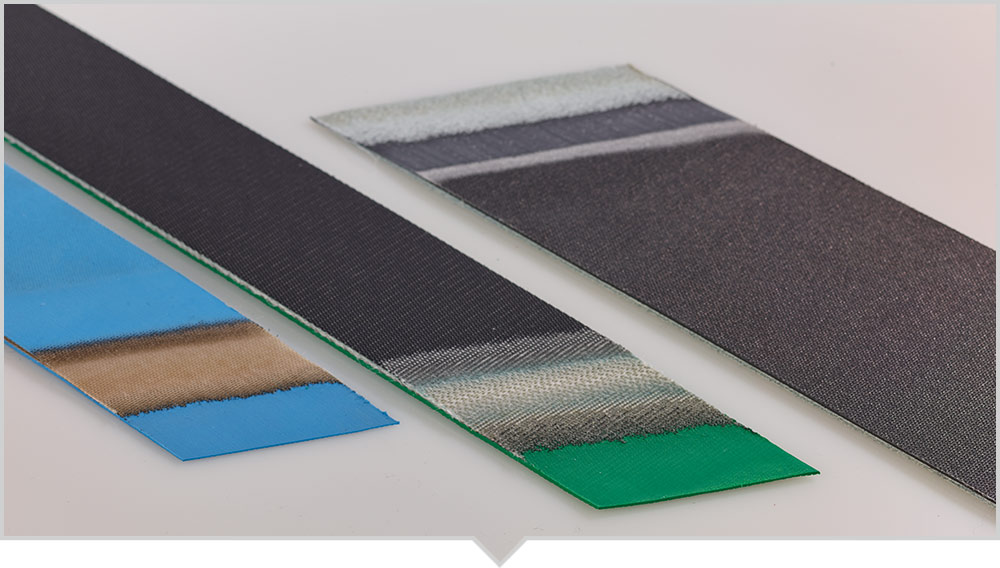

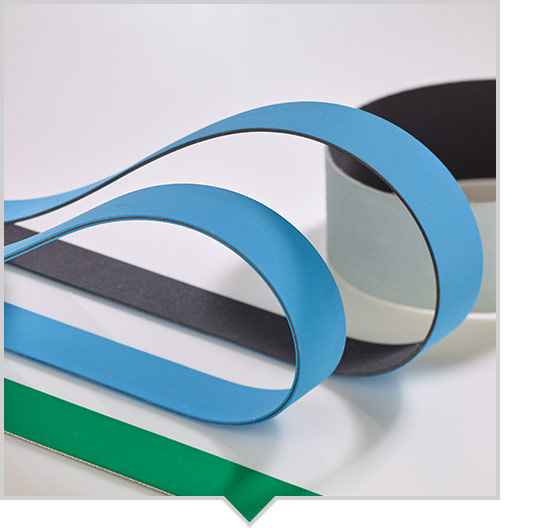

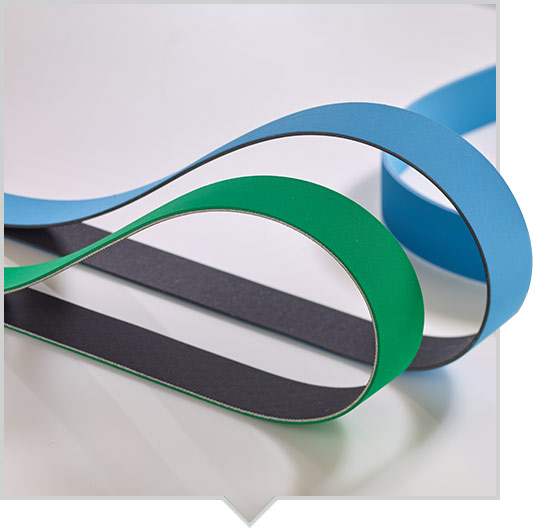

KLUMP flat belts have proved worldwide as an efficient apparatus for mechanical power transmission and for the transport of different industrial goods. Our flat belts are used successfully in open drives, drives with multiple rollers, tangential drives, drives with conveyor rollers, as well as with double-sided power transmission. Our drive and conveyor belts made of polyamide, polyester, and aramid meet the highest standards and are used, for example, in the printing and paper, wood and textile industry. They are combined with synthetic rubber,

chrome leather and/or textile fabrics. For special purposes of use we also offer special coatings of all kinds. Through a continuous development and careful selection of material qualities we achieve optimal transit times for your plants.