The technology for (almost) unlimited possibilities

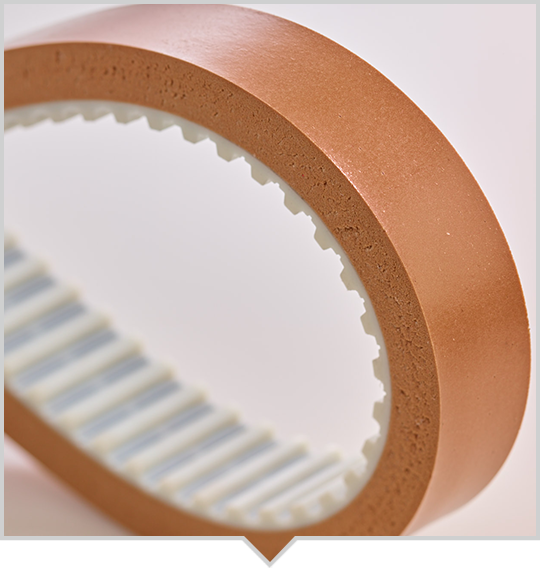

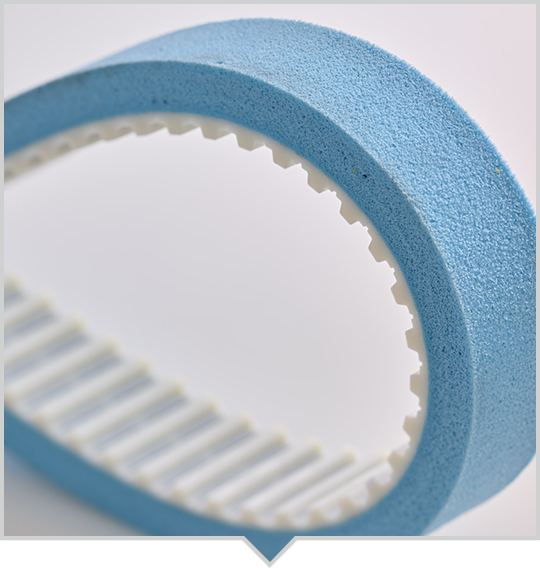

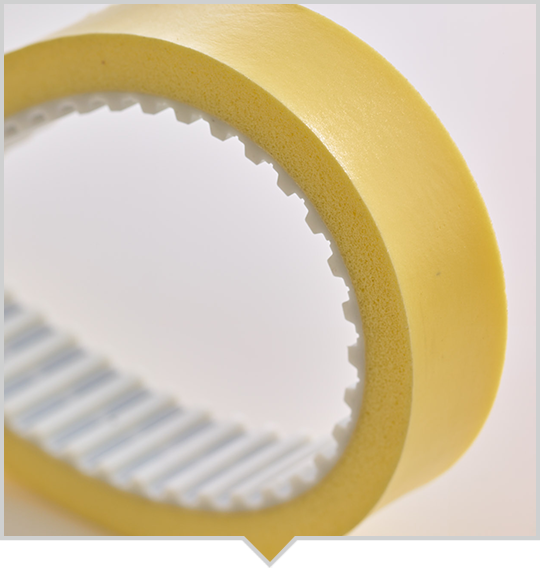

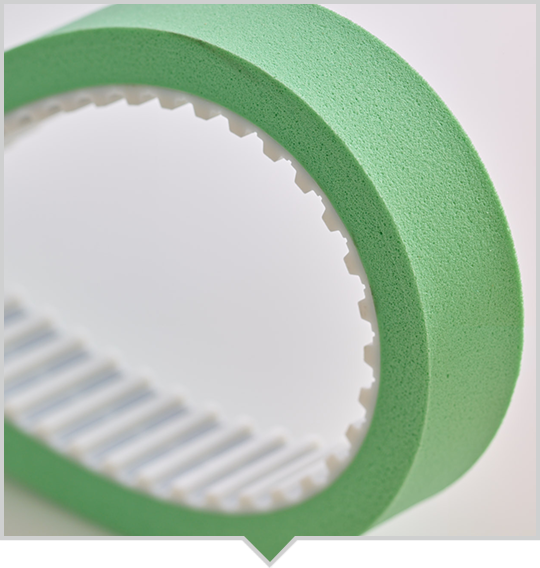

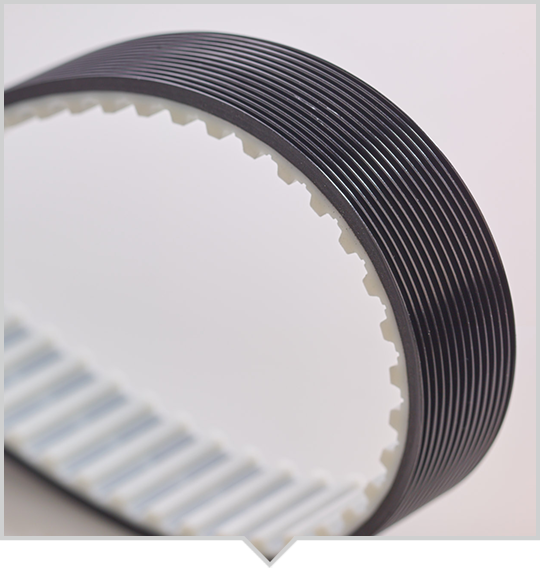

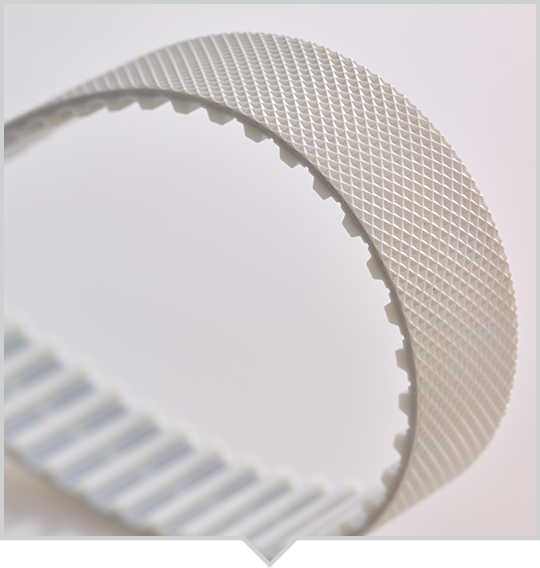

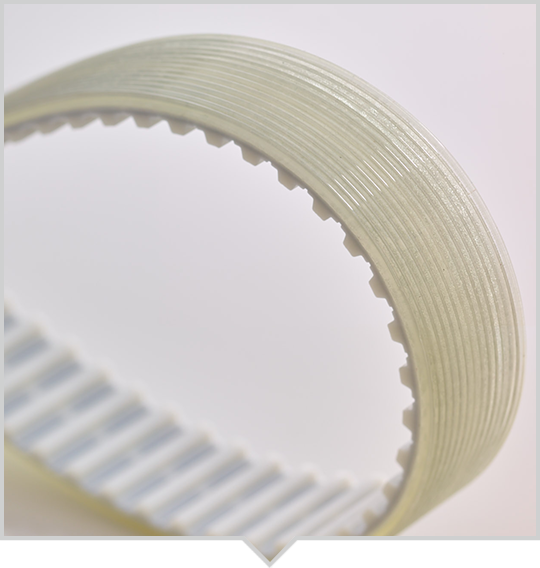

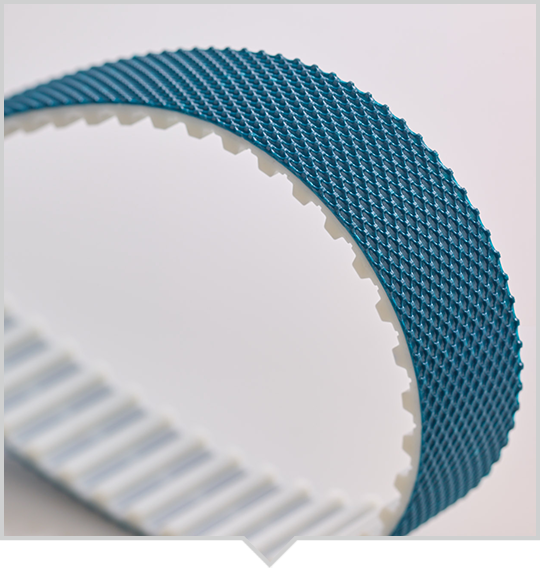

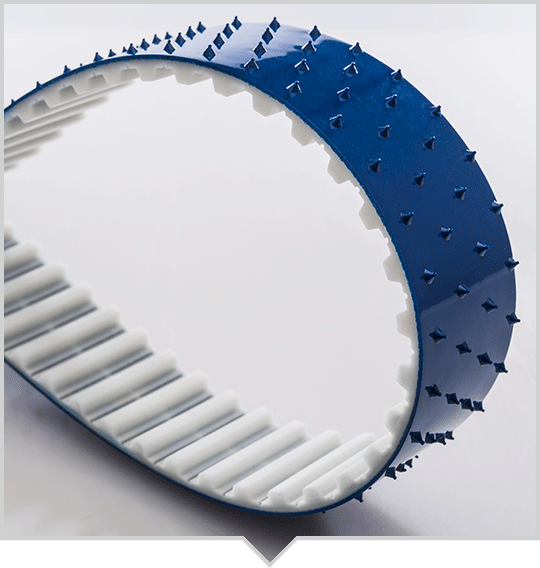

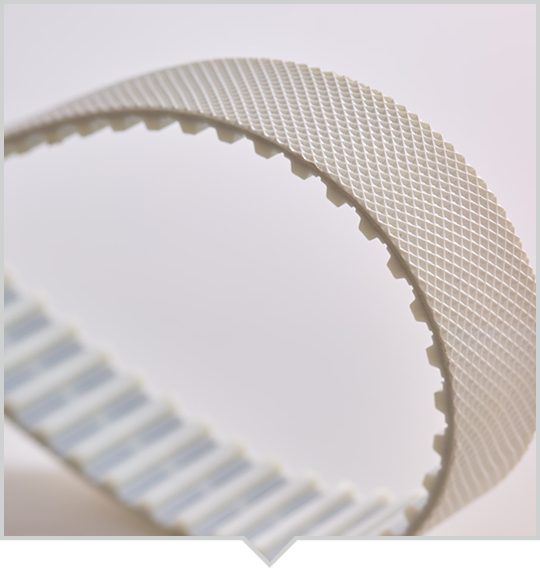

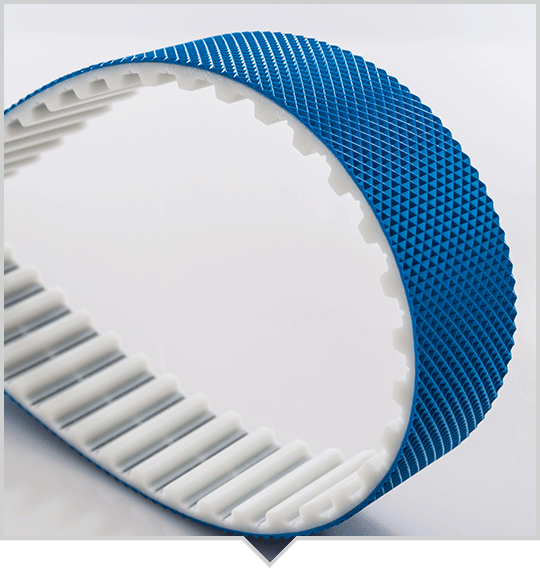

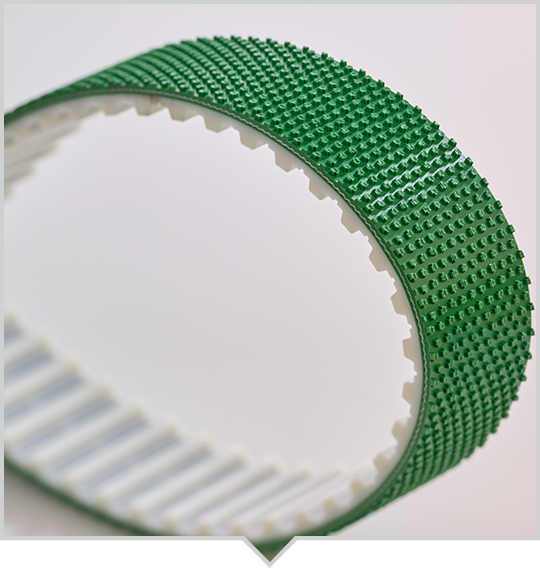

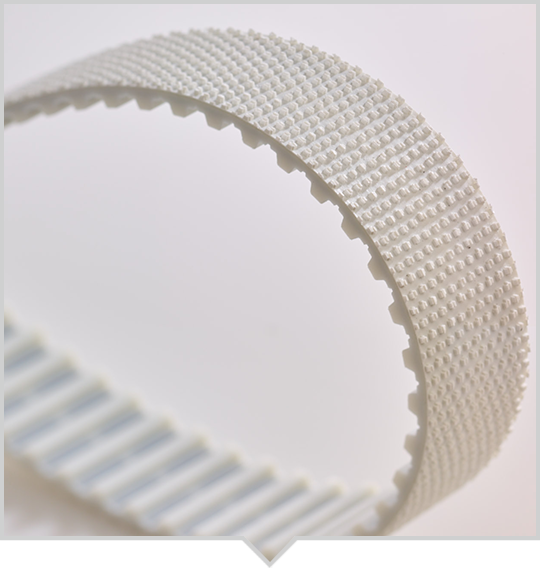

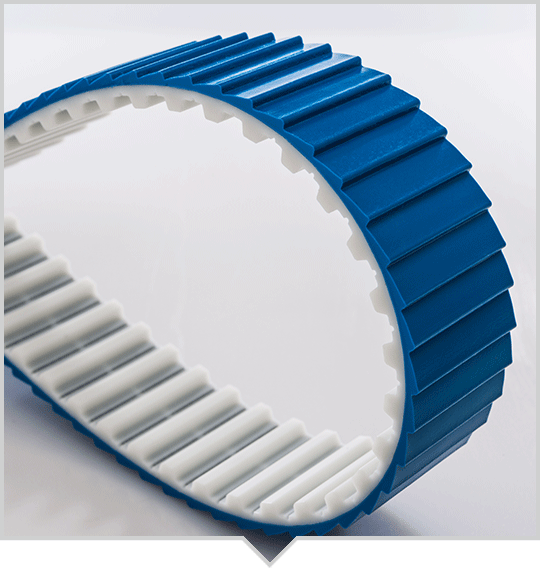

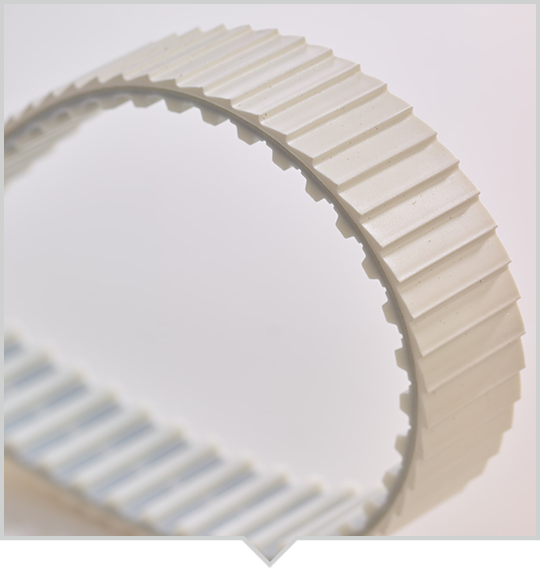

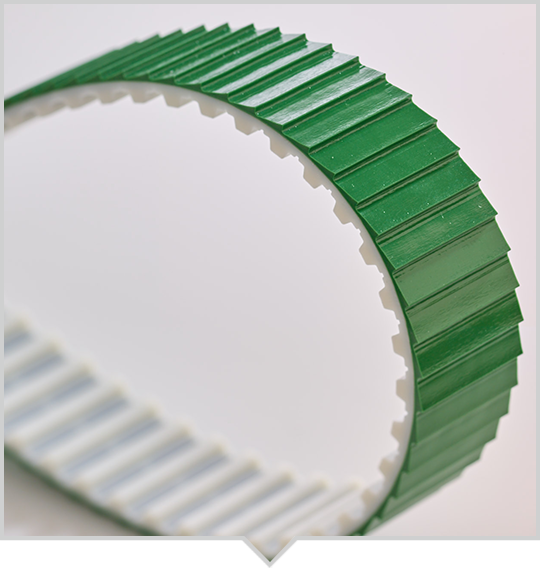

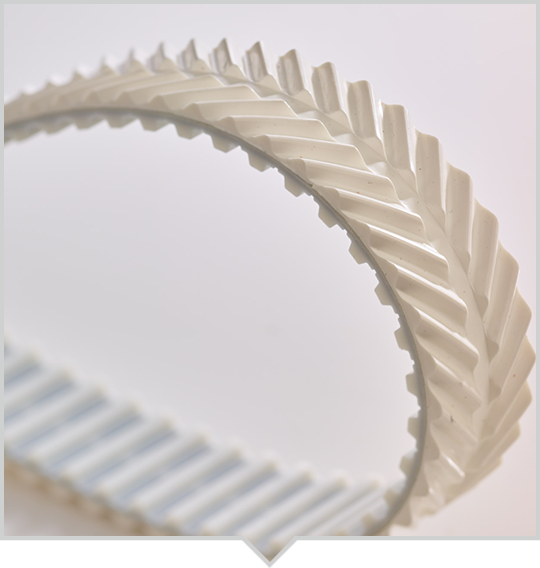

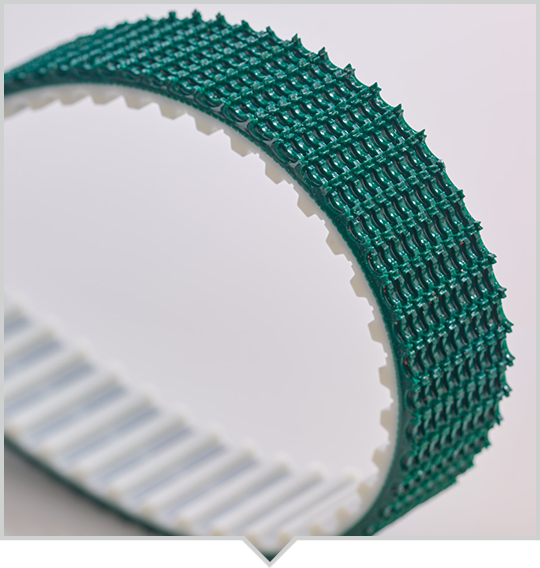

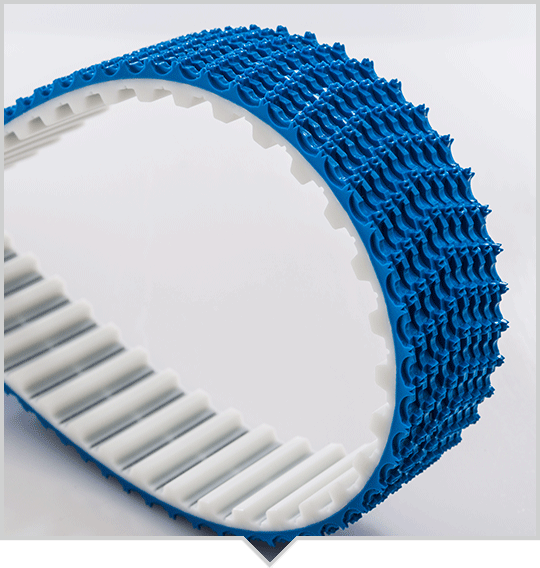

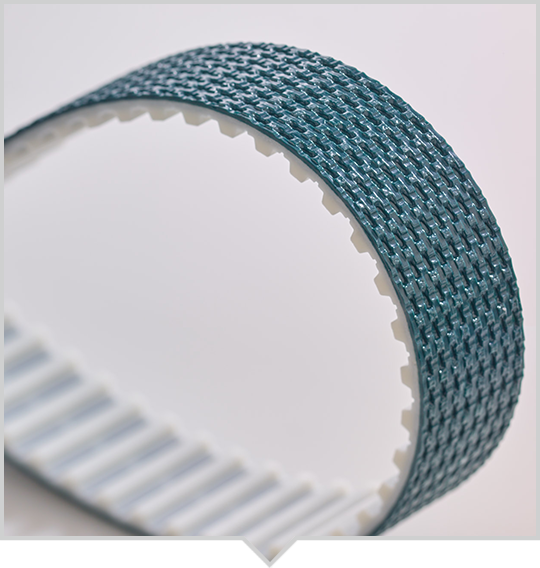

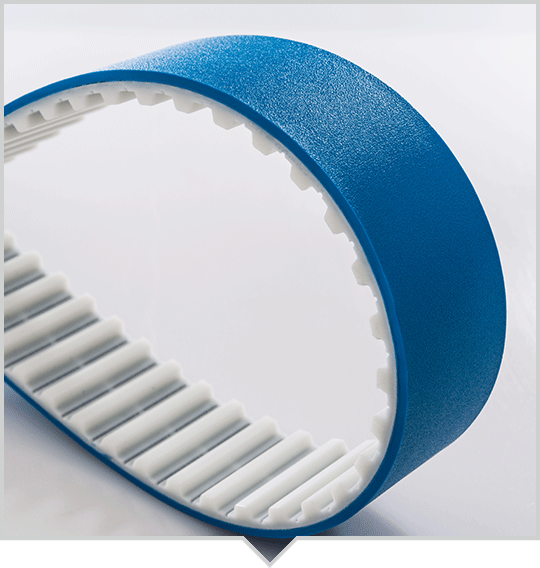

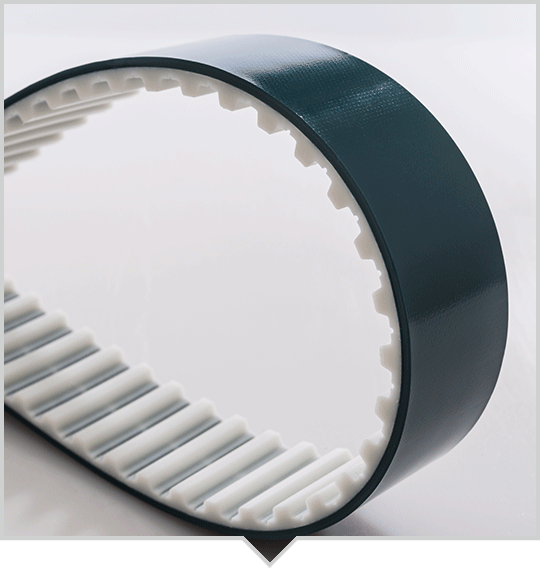

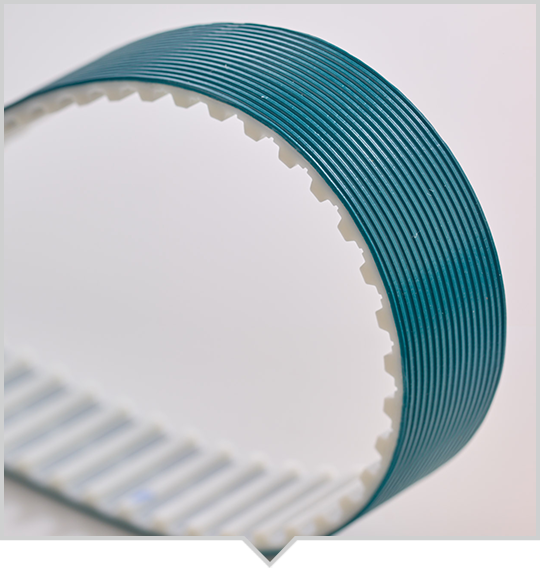

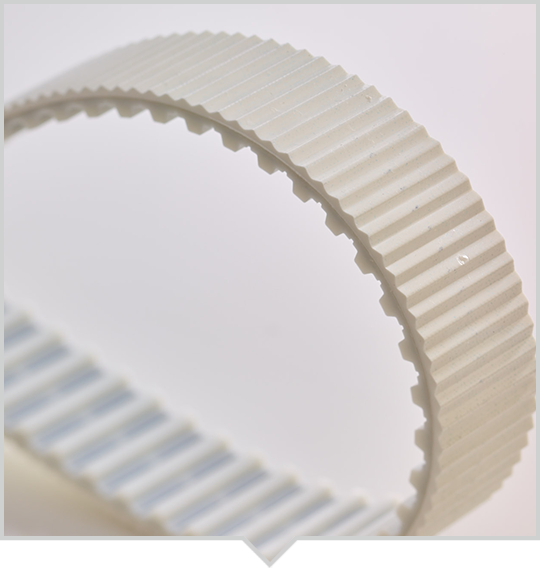

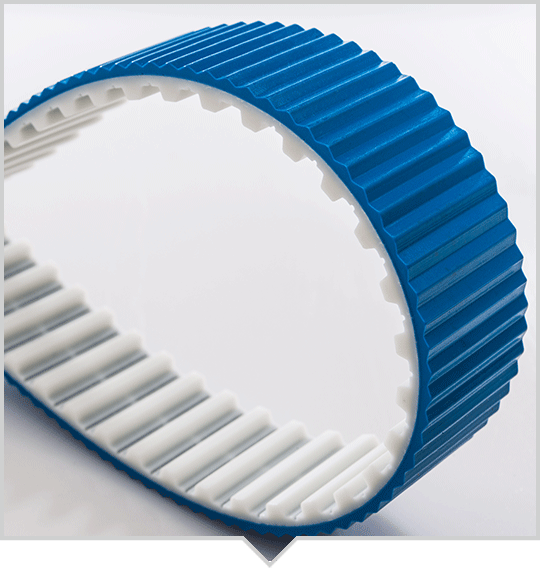

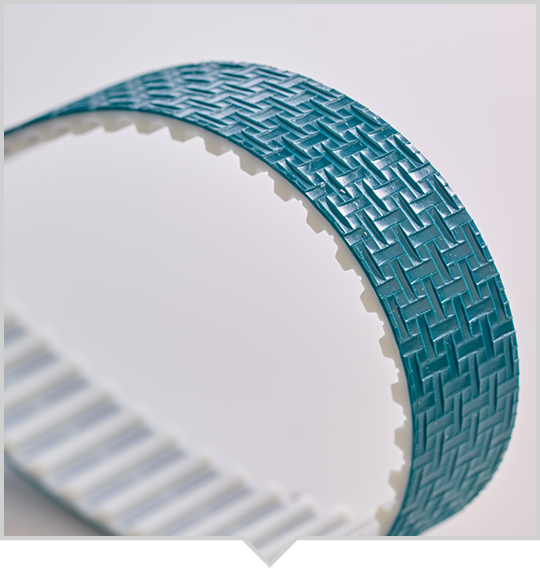

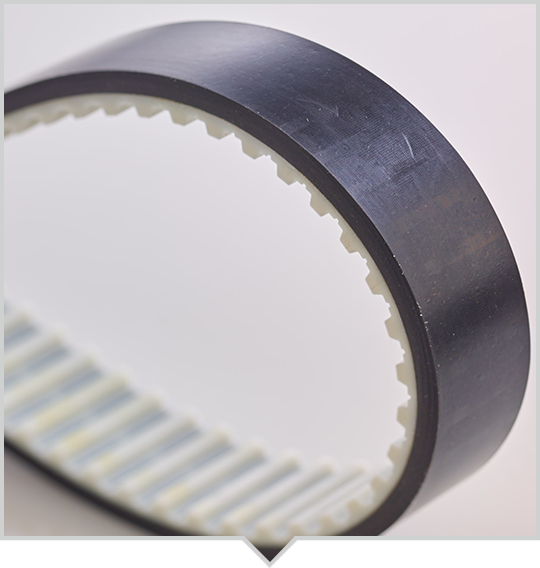

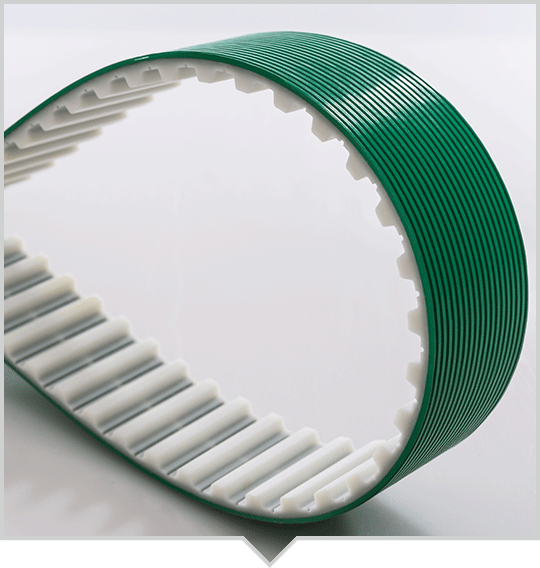

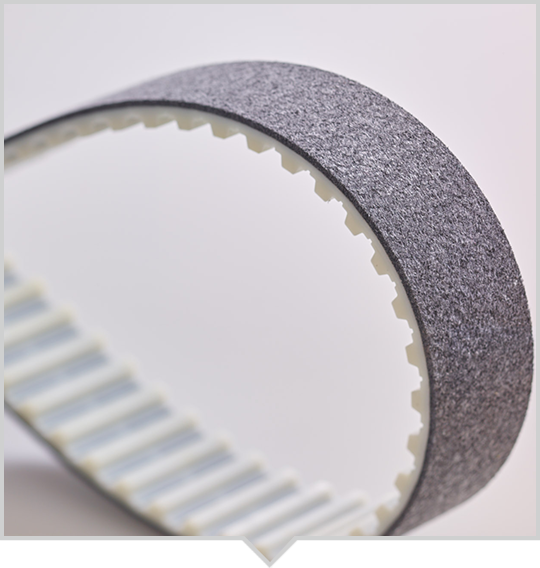

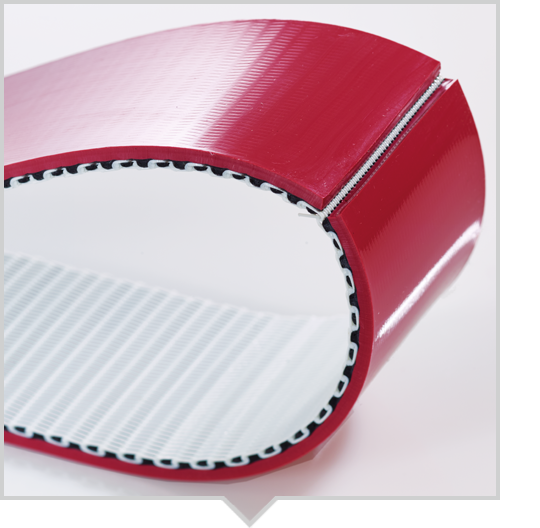

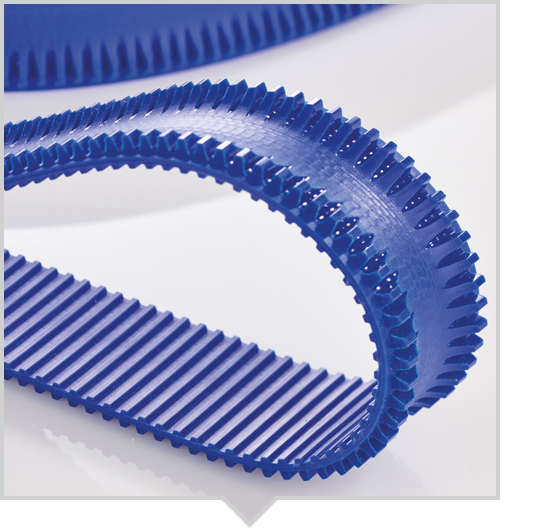

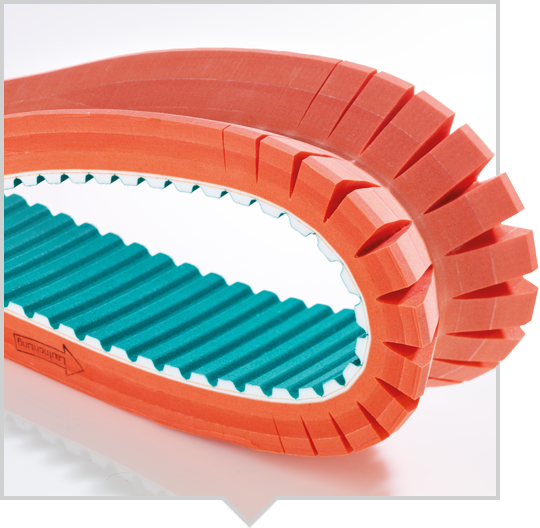

KLUMP conveyor belts, timing belts, flat belts and V-ribbed belts can be fitted subsequently with the wide range of coatings. As a result, their possibilities of use are almost limitless.

In addition, polished surfaces, millings, incisions, any perforations and special designs can be manufactured according to your specifications or drawings. Materials such as PVC, polyurethane, silicone, rubber, leather and felt are possible to be used as back side coatings. On request, we can combine or double different coatings.

We can gladly send you more detailed information material, patterns folder, as well as technical data sheets for the individual products and create offers matching to your wishes.

The following is an overview of our coatings.