Die Technik für (beinahe) unbegrenzte Möglichkeiten

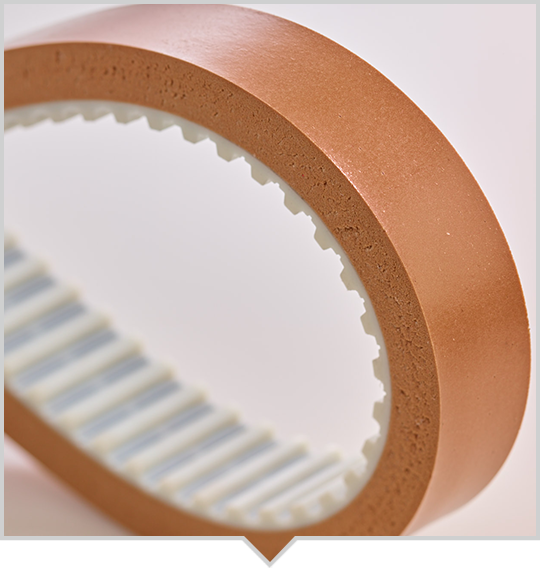

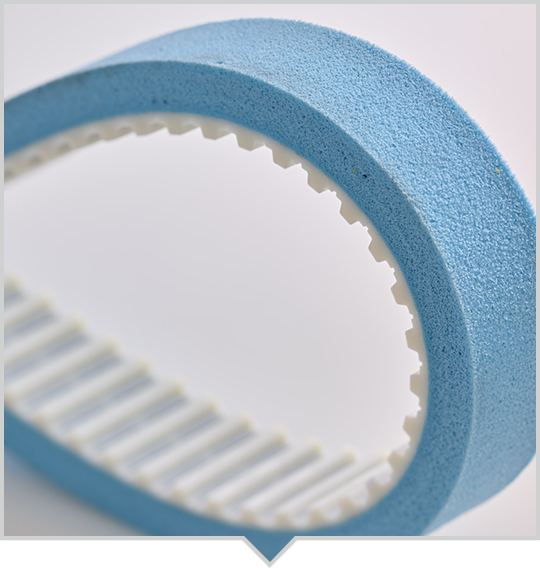

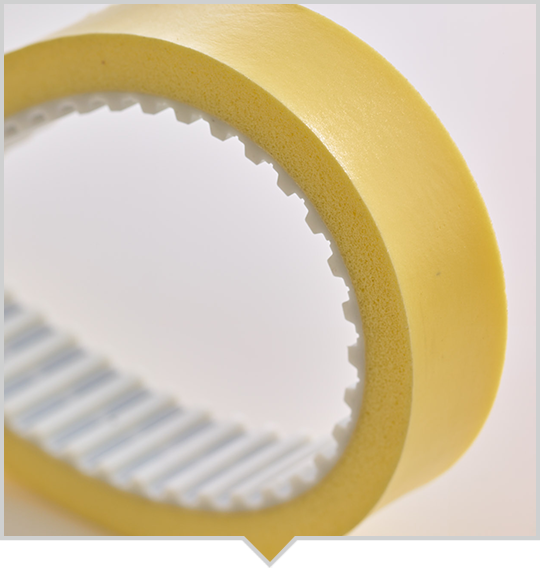

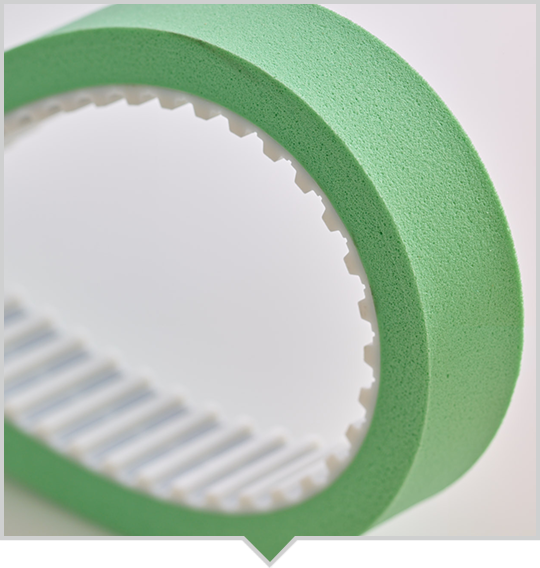

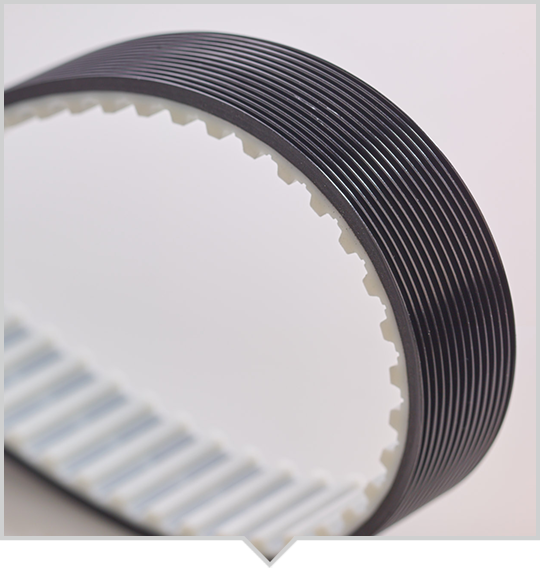

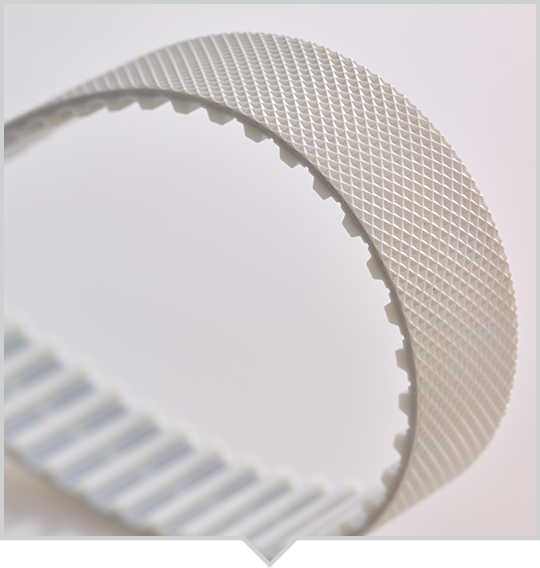

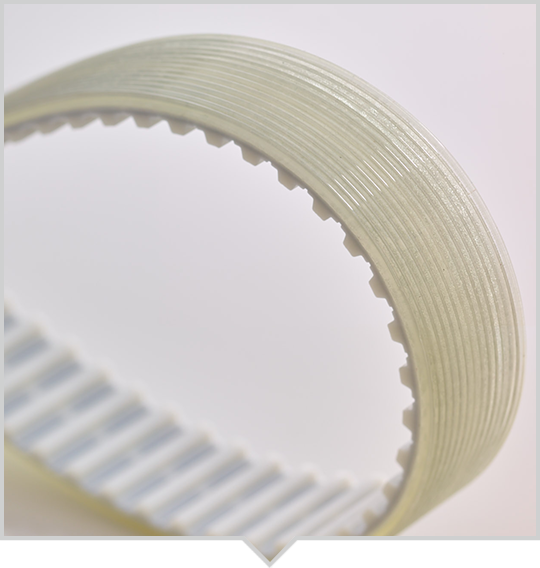

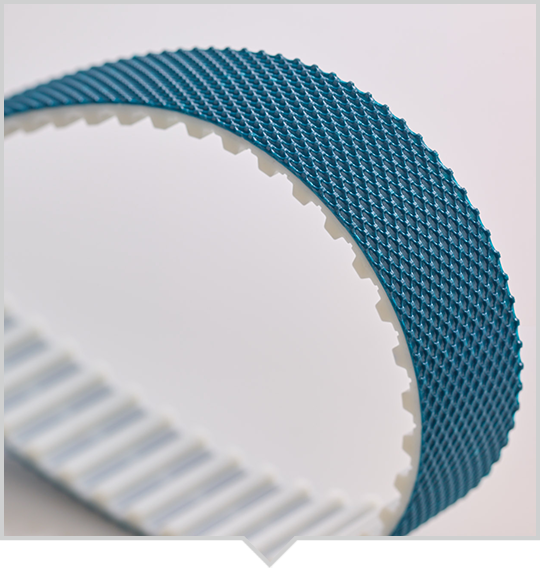

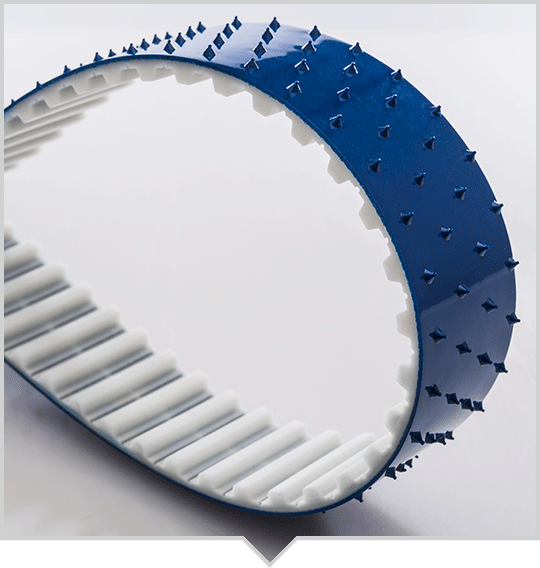

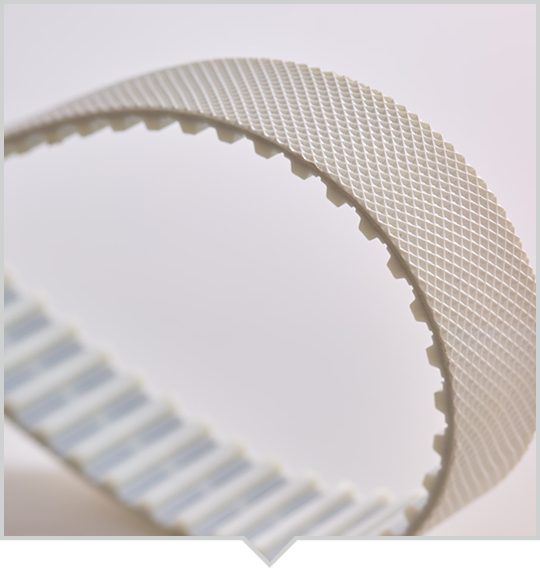

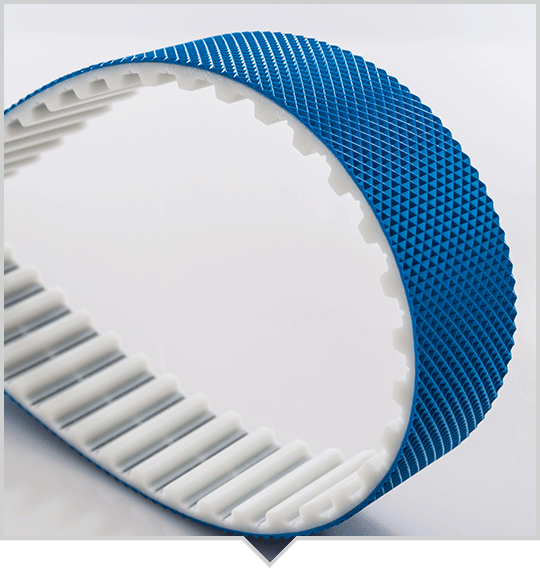

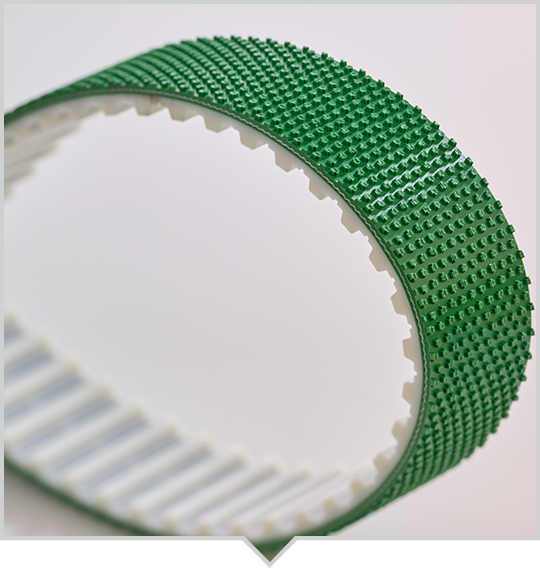

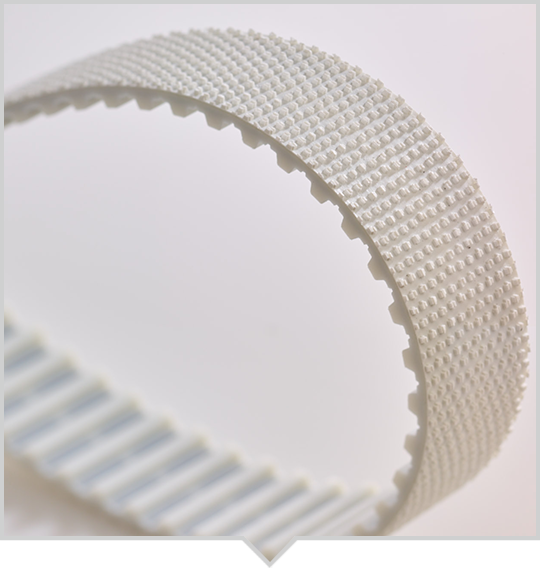

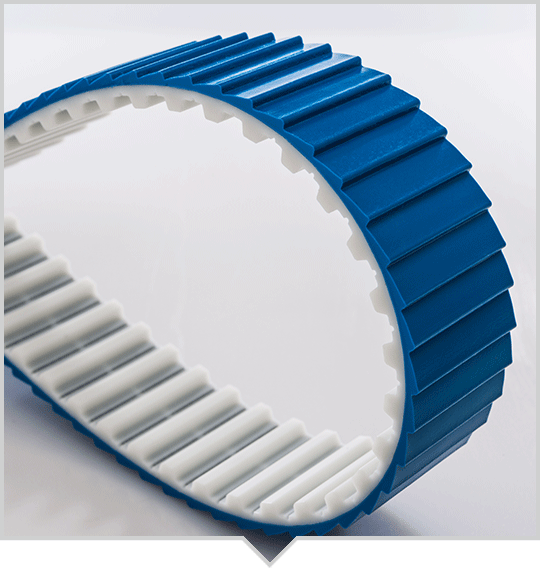

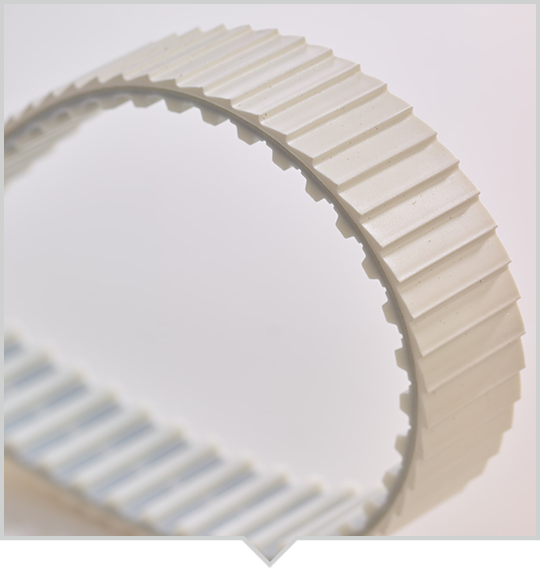

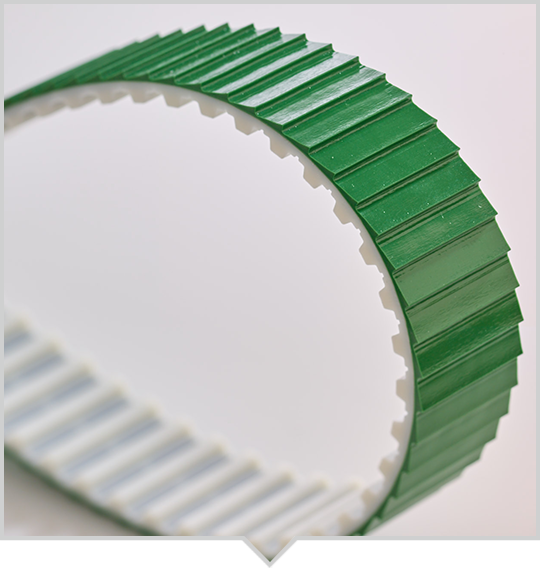

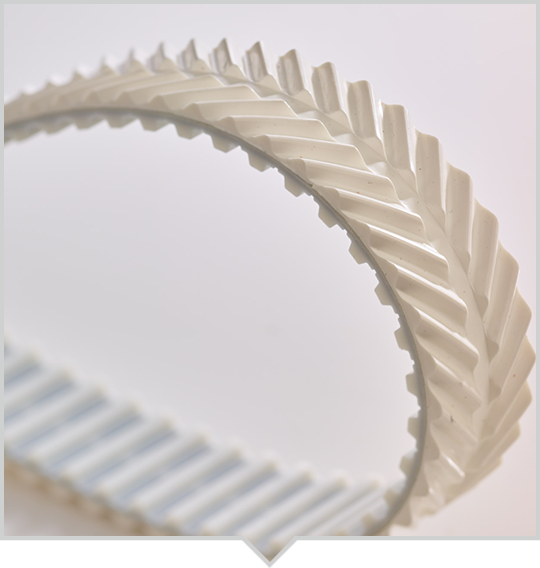

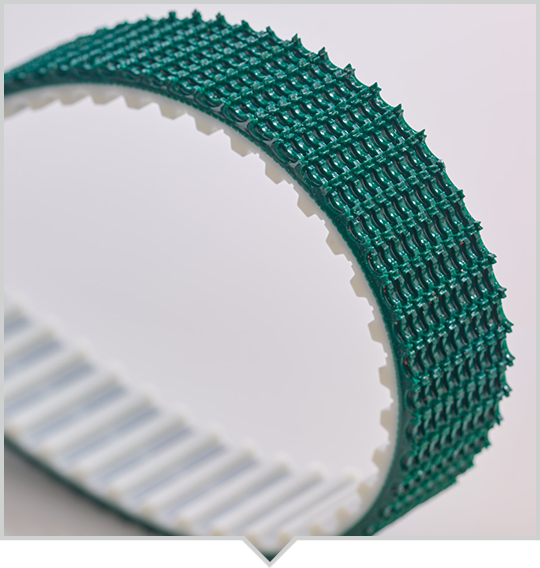

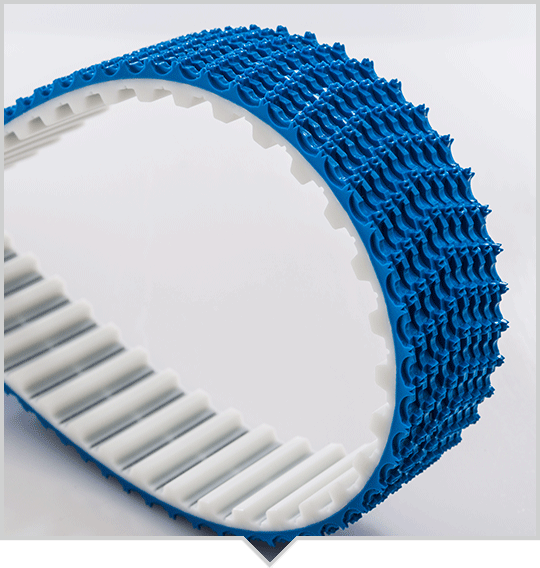

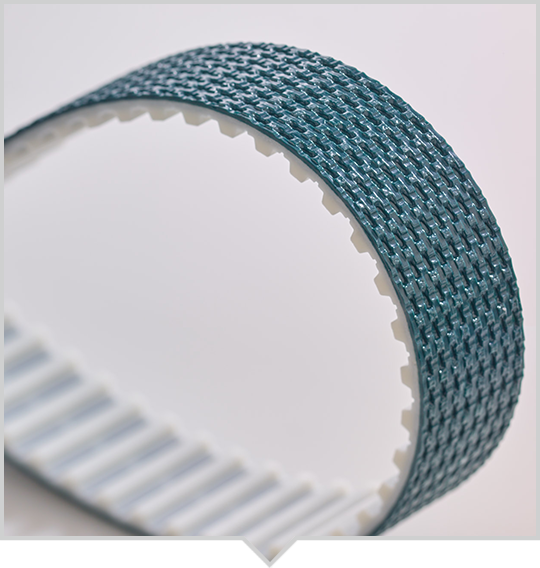

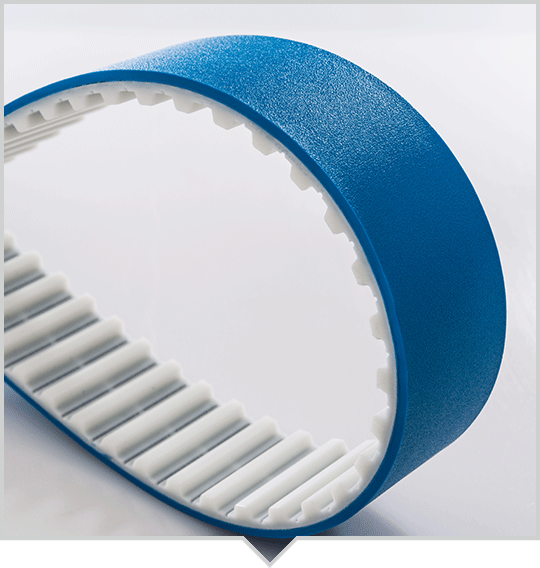

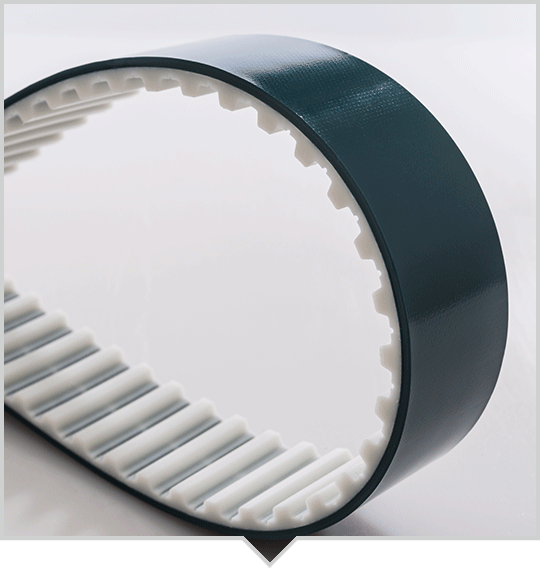

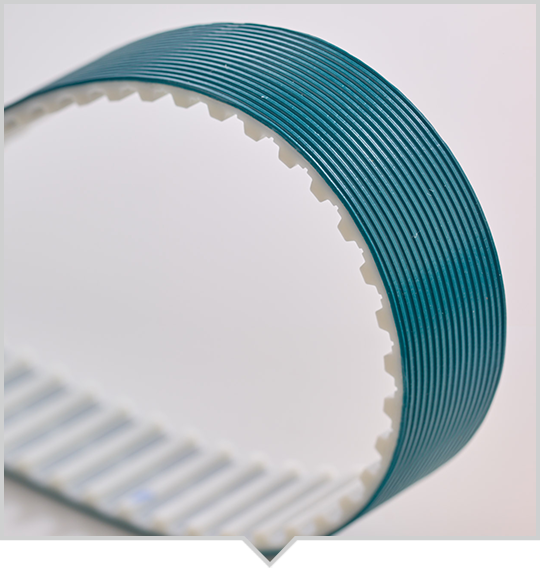

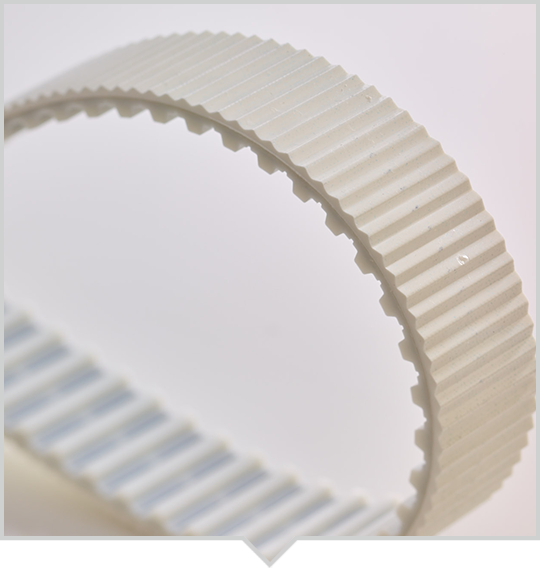

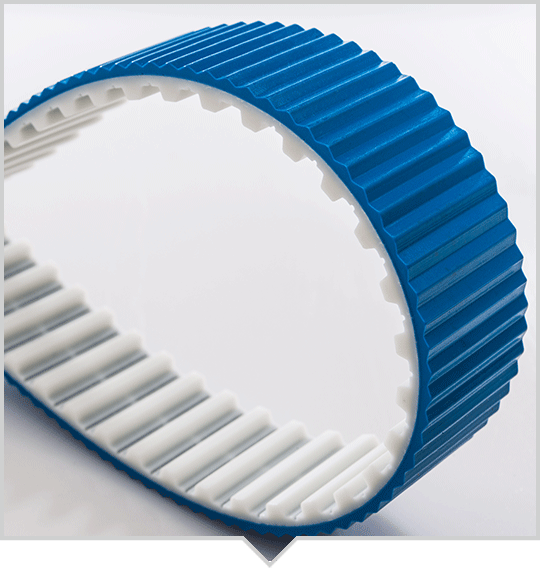

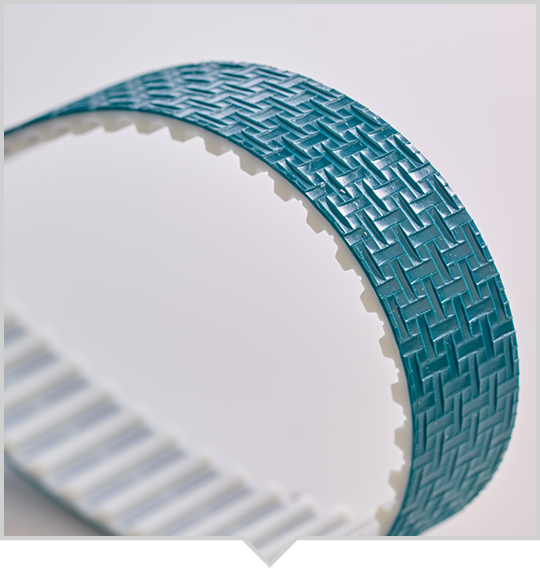

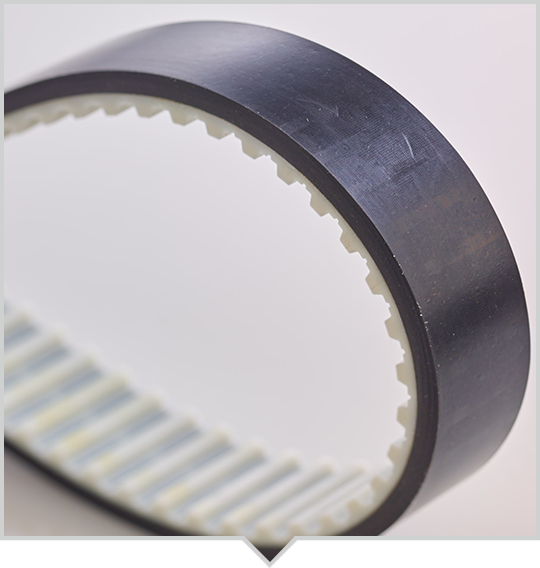

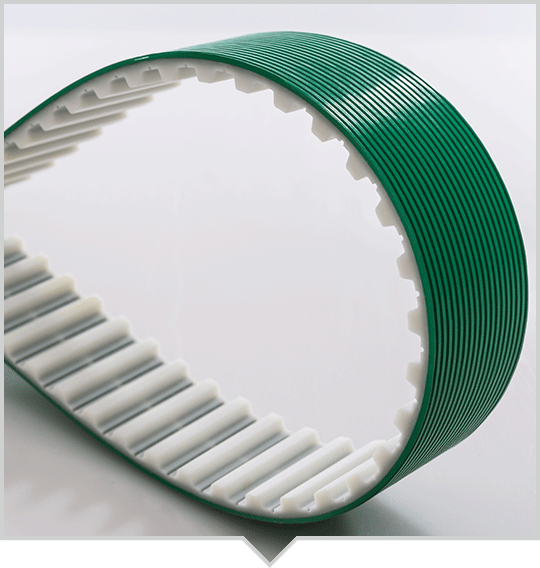

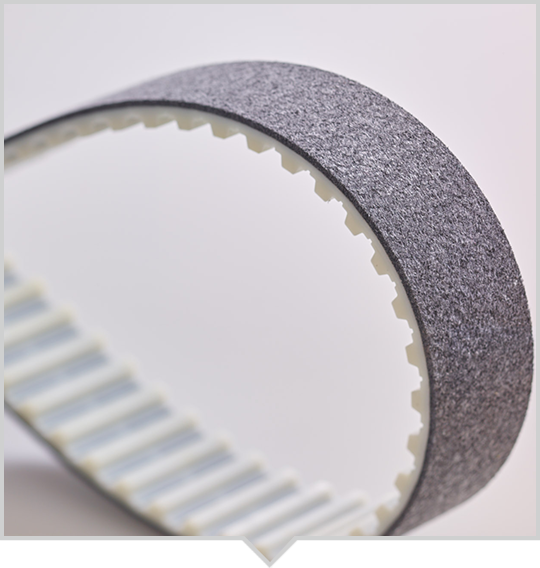

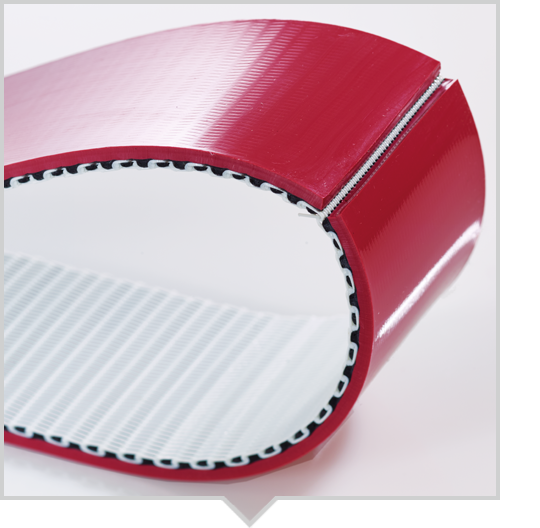

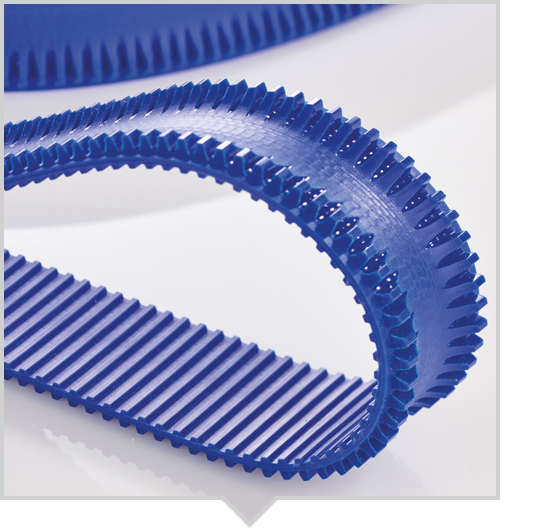

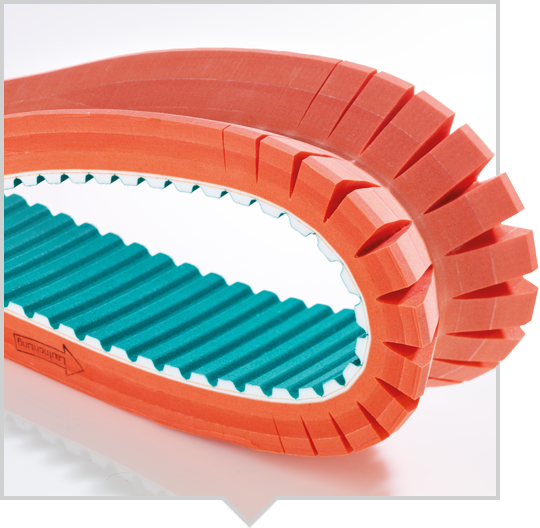

Ein KLUMP-Transportband, Zahnriemen, Flachriemen und Keilrippenriemen kann nachträglich mit einer Beschichtung unterschiedlichster Art ausgerüstet werden. Dadurch sind die Einsatzmöglichkeiten nahezu unbegrenzt.

Zusätzlich können geschliffene Oberflächen, Fräsungen, Sommerungen, beliebige Lochungen und Sonderanfertigungen gemäß Ihrer Vorgaben oder Zeichnungen gefertigt werden. Als Rückenbeschichtungen sind z. B. Materialien aus PVC, PU, Silikon, Kautschuk, Leder und Filz möglich. Auf Wunsch können auch unterschiedliche Beschichtungen kombiniert bzw. doubliert werden.

Wir übersenden Ihnen gern ausführlicheres Informationsmaterial, Musterordner sowie technische Datenblätter zu den einzelnen Produkten und erstellen auf Ihre Wünsche abgestimmte Angebote.

Nachstehend finden Sie unsere Beschichtungen im Überblick.